Wilo-Sub TWI 4.05

Design

Submersible-motor pump, multistage

Type key

e.g. Wilo-Sub TWI 4.01-09-B

TWI Submersible pump

4 Diameter of the hydraulic unit in inches ["]

01 Nominal volume flow [m3/h]

09 Number of hydraulic stages

B Series generation

Application

• For water and potable water supply from boreholes

and rainwater storage

• Process water supply

• For municipal water supply, sprinkling and irrigation

• Pressure boosting

• Lowering the water level

• For pumping water in industrial applications

• For pumping water without long-fibre and abrasive constituents

Special features/product benefits

• Simple maintenance due to rapid installation and dismantling

• Integrated non-return valve

• Vertical and horizontal installation possible

Technical data

• Mains connection: 1~230 V, 50 Hz or 3~400 V, 50 Hz

• Immersed operating mode: S1

• Fluid temperature: 3-30 °C

• Minimum motor flow: 0.1 m/s

• Max. sand content: 50 g/m3

• Max. number of starts: 20/h

• Max. submersion depth: 150 m

• Protection class: IP 68

• Pressure port: Rp 1½ - Rp 2

Equipment/function

• Multistage submersible-motor pump with radial impellers

• Integrated non-return valve

• NEMA coupling

• Single-phase or three-phase AC motor

• Motor with hermetically cast motor

Materials

• Hydraulic housing: 1.4301 stainless steel

• Impellers: 1.4301 stainless steel

• Hydraulics shaft: 1.4057 stainless steel

• Motor housing: 1.4301 stainless steel

• Motor shaft: 1.4305 stainless steel

Description/design

Submersible-motor pump for vertical or horizontal installation.

Hydraulics

Multistage submersible-motor pump with 4" NEMA connection and radial or semi-axial impellers with sectional construction. Integrated non-return valve. All parts in contact with the fluid are made of cor- rosion-free materials.

Motor

Corrosion-free single-phase or three-phase AC motor for direct starting. Sealed, hermetically cast stator, resin-impregnated, with enamel-insulated winding, self-lubricating bearing, with water-glycol filling.

Cooling

The motor is cooled by the fluid. The motor must always be immersed when operated. The limit values for maximum fluid temperature and minimum flow velocity must be adhered to. Vertical installation is possible with or without cooling jacket. Cooling jacket is required for horizontal installation.

Scope of delivery

• Hydraulics + motor fully mounted

• 1.5/2.5 m connecting cable in accordance with VDE/KTW with 4x1.5 mm2 cross-section

• Single-phase version including switchbox with capacitor, thermal motor protection and On/Off switch

• Installation and operating instructions

|

Wilo-Sub... |

Dimensions |

Weight |

Installation |

|||||||

|

W |

C1 |

C2 |

E |

L |

W |

0 3) |

Shroud* |

Unit |

– |

|

|

[mm] |

[kg] |

– |

||||||||

|

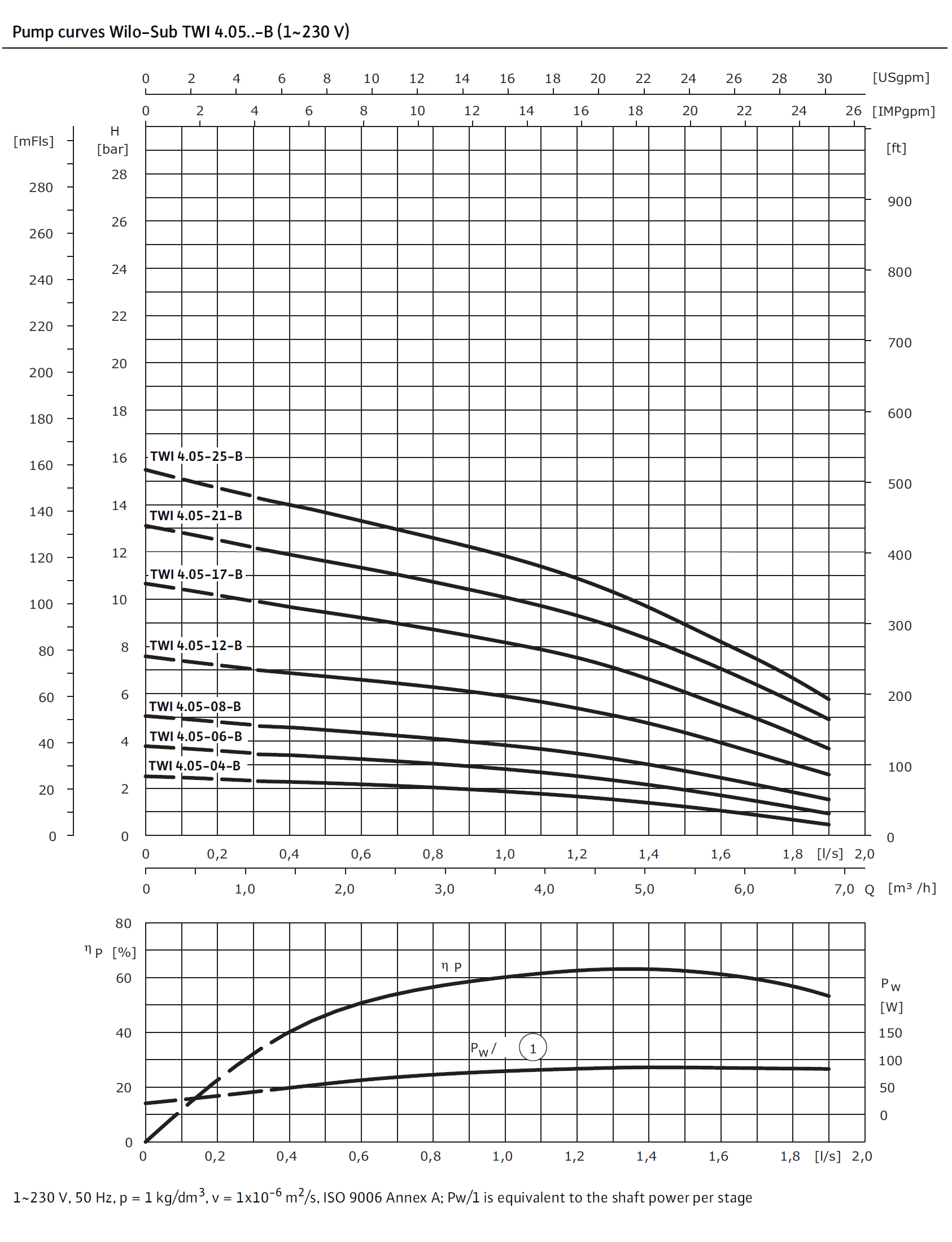

TWI 4.05-04-B |

920 |

329 |

– |

139.7 |

509 |

500 |

98 |

33 |

12 |

A, B, D, E, F |

|

TWI 4.05-06-B |

920 |

371 |

– |

139.7 |

551 |

500 |

98 |

33 |

12.5 |

A, B, D, E, F |

|

TWI 4.05-08-B |

920 |

441 |

– |

139.7 |

621 |

500 |

98 |

33 |

14.2 |

A, B, D, E, F |

|

TWI 4.05-12-B |

1220 |

610 |

– |

139.7 |

762 |

750 |

98 |

36 |

18.4 |

A, B, D, E, F |

|

TWI 4.05-17-B |

1220 |

791 |

– |

139.7 |

971 |

750 |

98 |

36 |

22.9 |

A, B, D, E, F |

|

TWI 4.05-21-B |

1520 |

875 |

355 |

139.7 |

1055 |

750 |

98 |

38 |

23.8 |

A, B, D, E, F |

|

TWI 4.05-25-B |

1520 |

959 |

439 |

139.7 |

1139 |

750 |

98 |

38 |

24.5 |

A, B, D, E, F |

|

Wilo-Sub... |

Mains connection |

Motor diameter |

Nominal motor power |

Nominal current |

Length of connection cable |

Cable cross- section |

|

– |

0 |

P2 |

IN |

L |

– |

|

|

– |

["] |

[kW] |

[A] |

[m] |

[mm2] |

|

|

TWI 4.05-04-B |

1~230 V, 50 Hz |

4 |

0.55 |

4.3 |

1.5 |

4G1,5 |

|

TWI 4.05-06-B |

1~230 V, 50 Hz |

4 |

0.55 |

4.3 |

1.5 |

4G1,5 |

|

TWI 4.05-08-B |

1~230 V, 50 Hz |

4 |

0.75 |

5.7 |

1.5 |

4G1,5 |

|

TWI 4.05-12-B |

1~230 V, 50 Hz |

4 |

1.5 |

10.6 |

1.5 |

4G1,5 |

|

TWI 4.05-17-B |

1~230 V, 50 Hz |

4 |

2.2 |

15.5 |

1.5 |

4G1,5 |

|

TWI 4.05-21-B |

1~230 V, 50 Hz |

4 |

2.2 |

15.5 |

1.5 |

4G1,5 |

|

TWI 4.05-25-B |

1~230 V, 50 Hz |

4 |

2.2 |

15.5 |

1.5 |

4G1,5 |